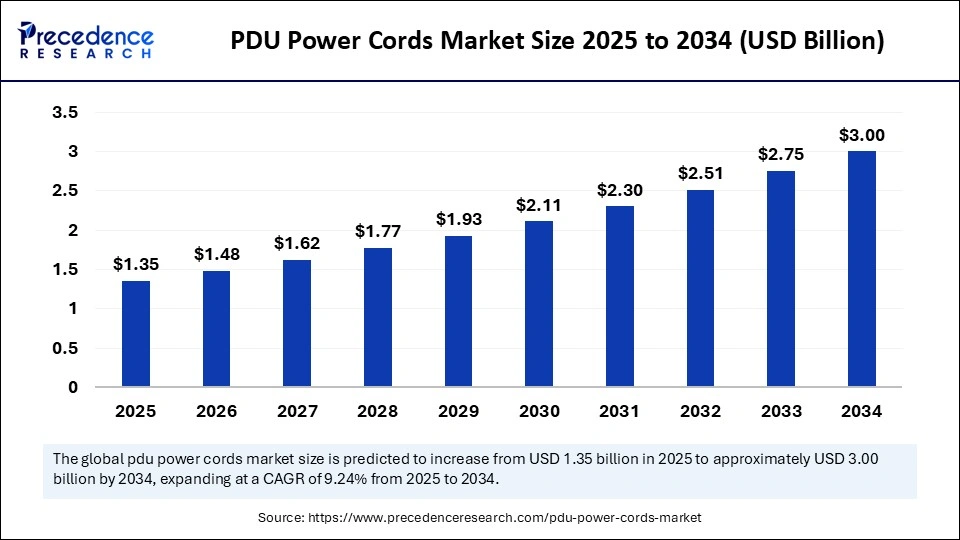

The global PDU power cords market size stood at USD 1.24 billion in 2024 and is forecasted to climb from USD 1.35 billion in 2025 to approximately USD 3.00 billion by 2034, expanding at an impressive CAGR of 9.24% over the forecast period. This sustained growth stems from expanding digital infrastructure, surging investments in automation and renewables, and increased EV charging deployment. As industries demand safer, longer-lasting power solutions, PDU power cords, known for toughness and reliability, are becoming indispensable on the global stage.

PDU Power Cords Market Key Points

-

The market is valued at USD 1.24 billion in 2024, forecast to surpass USD 3.00 billion by 2034.

-

North America remains the leading region, setting benchmarks in innovation and demand.

-

Asia Pacific emerges as the fastest-growing region, powered by rapid industrialization, e-commerce, and smart grid investments.

-

Dominant market segments include standard off-the-shelf cordsets, with custom/molded and modular assemblies rising fastest.

-

IEC C13/C14 and C19/C20 are the top connectors due to compatibility and regulatory acceptance, while locking and regional connectors are growing quickly.

-

Copper with PVC/thermoplastic insulation leads as the premium conductor for cost and performance, while LSZH, high-temp, and armored cords expand into regulated/dependent sectors.

-

Data centers and colocation facilities are the biggest end-users, followed by fast-growing demand from telecom and edge computing sectors.

PDU Power Cords Market Revenue Table

| Metric | Value (USD) |

|---|---|

| Global Market Size (2024) | 1.24 Billion |

| Market Size (2025) | 1.35 Billion |

| Projected Market (2034) | 3.00 Billion |

| CAGR (2025-2034) | 9.24% |

How is AI Shaping the PDU Power Cords Market?

AI is revolutionizing the way manufacturers design, predict, and monitor PDU power cords. Advanced AI-powered material simulations accelerate cord development, boosting thermal stability and conductivity. In industrial environments, AI-driven monitoring systems enable predictive maintenance, minimizing downtime and lowering operational costs. Machine learning models streamline demand forecasting and inventory planning, while intelligent testing guarantees higher levels of quality and compliance. This convergence of AI and material engineering powers the next wave of innovation in cord manufacturing and reliability.

AI also transforms the market by increasing testing speeds and compliance with global safety standards. Predictive analytics enacted by AI-integrated systems are pivotal for manufacturers to respond proactively to potential failures. Ultimately, the adoption of AI deepens efficiency, speeds up the innovation cycle, and helps foster smarter supply chains.

What Are the Key Market Growth Factors?

-

Rapid industrial automation and robotics drive demand for durable, long-lasting cords able to withstand extreme operational environments.

-

The acceleration of renewable projects requires robust, weather-resistant solutions for solar and wind installations.

-

EV infrastructure growth necessitates high-quality cords, especially for charging in volatile conditions.

-

Construction and mining industries increasingly rely on heavy-duty cords for safety and performance.

-

Industry moves toward stricter safety and regulatory standards, prompting design innovation in cord manufacturing.

Are There New Opportunities and Trends?

What will drive sustainable breakthroughs in the coming years?

Innovating with biodegradable and recyclable polyurethane opens up sustainable possibilities for PDU cord production. Electric vehicle charging stations and smart grid projects offer lucrative growth prospects as the world pivots towards greener energy. Custom hybrid cords capable of power delivery and real-time data transmission align with Industry 4.0 expansion; so do specialty designs for robotics within healthcare and logistics.

How will Asia and Africa’s infrastructure affect cord markets?

Rapid regional infrastructure growth, especially in Asia and Africa, provides vast untapped opportunity for manufacturers of PDU power cords.

Regional Analysis: Who’s Leading and Why?

North America dominates, powered by investments in industrial automation, renewables, strong EV charging infrastructure, and rapid AI adoption in smart factories. Asia Pacific accelerates fastest—thanks to growth in urban manufacturing, digital infrastructure, EV charging rollouts, and favorable local policy for innovation.

Segmentation Review

-

Product Type: Standard cordsets dominate, while custom/molded and modular assemblies grow.

-

Connector Type: IEC C13/C14, C19/C20 standard, with locking/specialized variants surging.

-

Voltage Rating: 16–32A cords lead mainstream, with three-phase/high-current cords rising for hyperscale and HPC clusters.

-

Cable Material: Copper/PVC insulations stand out, and LSZH/high-temp/armored cords spike in regulated industries.

-

Length/Form Factor: Standard rack-length cords rule, with short jumper/custom designs growing.

-

PDU Compatibility: Basic/metered types dominate, while smart/managed cords see rapid adoption linked to AI.

-

Application/End-Use: Data centers and colocation dominate, followed by edge computing and telecom.

-

Installation Type: Field-installed cords are most popular, pre-terminated modular systems expanding.

-

Regions: North America leads; Asia Pacific expands fastest; Europe, Latin America, and MEA follow.

PDU Power Cords Market Companies

- Amphenol

- Belden

- Eaton / Tripp Lite

- HellermannTyton

- Hubbell

- Legrand / Eaton

- Molex

- Molex / Amphenol

- NEXANS

- Nidec

- Panduit

- Prysmian Group

- Schneider Electric / APC

- Southwire

- Tripp Lite

Challenges and Cost Pressures

Main challenges involve higher production costs (vs. PVC alternatives), volatile raw material prices (especially polyurethane), and regulatory hurdles across regions. Competition from substitutes and difficulties in recycling polyurethane present ongoing cost and technical obstacles. These factors may restrain adoption in price-conscious markets despite strong benefits.

Case Study Highlight

A leading data center operator in North America recently adopted AI-driven predictive maintenance on PDU power cords, reducing downtime by 30% and slashing emergency maintenance costs. This highlights how technological integration is reshaping operational standards and efficiency at scale.

Read Also: Sustainable Infrastructure Market

You can place an order or ask any questions. Please feel free to contact us at sales@precedenceresearch.com |+1 804 441 9344

- Lymphoma Treatment Market Size to Skyrocket USD 16.62 Billion by 2034 - September 16, 2025

- PDU Power Cords Market Size to Soar USD 3.00 Billion by 2034 - September 16, 2025

- Intelligent Platform Management Interface Market Size to Cross USD 2.88 Billion by 2034 - September 16, 2025