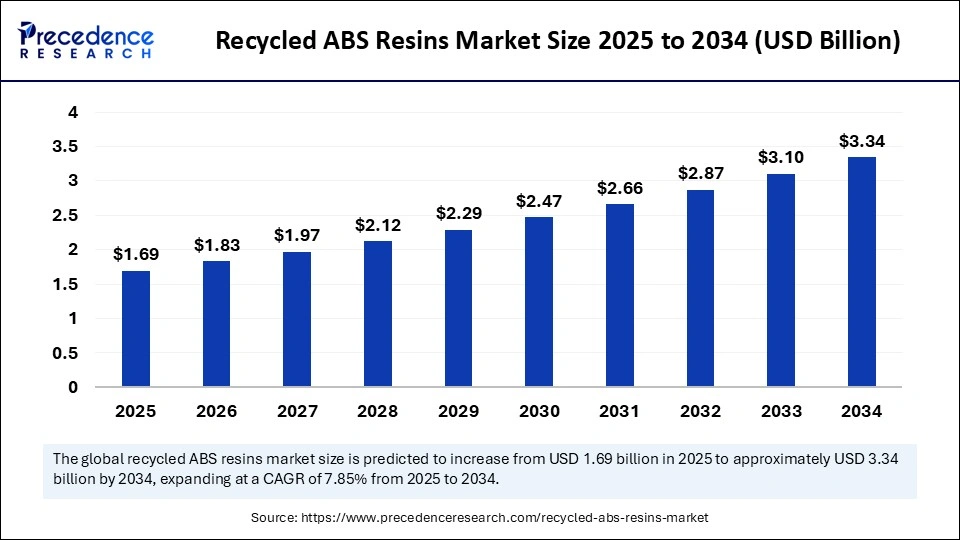

The global recycled ABS resins market is set to expand significantly, reaching an estimated valuation of USD 3.34 billion by 2034, up from USD 1.69 billion in 2025. This growth reflects a Compound Annual Growth Rate (CAGR) of 7.85% during 2025–2034, driven by increasing demand for sustainable materials, regulatory mandates, and advances in recycling technologies.

Recycled ABS resins, derived from post-consumer and post-industrial waste, are increasingly replacing virgin plastic in automotive, electronics, construction, and packaging sectors. The market benefits from robust growth stimulated by circular economy principles, technological innovations such as AI-enhanced recycling, and manufacturing shifts toward environmental sustainability. Regulations enforcing recycled content and consumer preference for eco-friendly products underpin this market’s optimistic trajectory.

Recycled ABS Resins Market Key Points

-

The global market size was USD 1.57 billion in 2024 and is forecast to grow to USD 3.34 billion by 2034.

-

North America is the dominant region, with Asia Pacific showing the fastest growth.

-

Post-industrial recycled ABS holds the largest market share due to its consistent quality and cost advantages.

-

Mechanical recycling remains the leading method, with chemical recycling emerging rapidly for high-purity applications.

-

Automotive and electronics industries are the top end-users driving demand.

-

Companies are increasingly investing in AI and chemical recycling technologies to improve yield and quality.

Recycled ABS Resins Market Size and Revenue Breakdown

| Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2024 | 1.57 | – |

| 2025 | 1.69 | 7.85 (2025-2034) |

| 2034 | 3.34 | – |

Artificial intelligence is revolutionizing the recycling value chain by enhancing the efficiency and precision of ABS waste sorting. AI-powered vision technologies enable better separation of ABS from other plastics, reducing contamination and increasing recycling yield. Machine learning also optimizes demand forecasting and logistics, reducing costs and supply chain disruptions.

In manufacturing, AI-driven real-time polymer quality monitoring ensures recycled resins meet stringent automotive and electronics quality standards. This dual role of AI enhances profitability and market confidence in recycled ABS as a viable alternative to virgin materials.

What Factors Are Fueling Market Growth?

The most significant growth drivers include rising regulatory requirements for recycled content, heightened consumer awareness about environmental impact, and cost competitiveness versus virgin ABS. Growing industrial sectors like automotive and electronics in emerging economies sustain material demand.

Innovations in mechanical and chemical recycling technologies improve quality and application scope. Additionally, government incentives and circular economy adoption worldwide contribute to accelerating market expansion.

What New Opportunities and Trends Are Emerging?

Why is post-industrial recycled ABS dominating the market? Post-industrial ABS constitutes the majority share, as manufacturing scrap offers better quality control and lowers contamination compared to post-consumer waste. This source is highly favored by automotive and electronics manufacturers for in-house recycling, enabling cost savings and sustainability benefits.

How is post-consumer recycled ABS gaining traction?

Despite challenges from contamination, advances in AI sorting and chemical recycling improve quality and unlock potential. Growing regulatory mandates and consumer demand for visible sustainability impact are driving rapid growth in this segment.

Are specialty grades like flame-retardant ABS rising in importance?

Safety and performance needs in automotive interiors and electronics are increasing demand for flame-retardant and specialty recycled ABS grades, which are among the fastest growing market segments.

What regions are leading and why?

Asia Pacific leads due to its manufacturing base and recycling infrastructure, while North America is the fastest-growing region, driven by strong environmental policies and technological innovation.

Recycled ABS Resins Market Segmentation Analysis

-

By Source: Post-industrial recycled ABS dominates due to superior quality and cost efficiency; post-consumer ABS shows fastest growth.

-

By Recycling Method: Mechanical recycling holds the largest share for its cost-effective scalability; chemical recycling grows rapidly for premium applications.

-

By Grade: Standard recycled ABS is dominant; flame-retardant and specialty grades are expanding quickly.

-

By Application: Automotive leads due to material demand and sustainability goals; electronics is the fastest growing due to e-waste recycling and consumer demand.

-

By Region: North America exhibits the fastest market growth, propelled by policy and AI adoption; Asia Pacific holds the largest market share with its extensive manufacturing ecosystem.

Recycled ABS Resins Market Companies

- MBA Polymers Inc.

- Veolia Environnement S.A.

- SUEZ Recycling and Recovery

- Envision Plastics

- Kuusakoski Recycling

- Green Ant Plastics

- Ravago Group

- Luxus Ltd.

- Covestro AG (recycled plastics division)

- BASF SE (circular economy initiatives)

- LyondellBasell Industries

- Toray Industries, Inc.

- ELIX Polymers

- WIS Plastics

- Alpek SAB de CV (DAK Americas recycling)

- Plastic Recycling Inc.

- Inteplast Group

- Plastic Energy Ltd.

- Trinseo PLC

- Avient Corporation

Challenges and Cost Pressures

The main challenges are maintaining quality consistency, especially for high-performance applications, and uneven recycling infrastructure globally. Chemical recycling remains capital-intensive and energy-demanding. Supply chain fluctuations and entrenched reliance on virgin ABS in price-sensitive markets pose resistance, underscoring the need for continued innovation and regulatory support.

Case Study Example

An automotive OEM implemented an AI-driven sorting system in collaboration with recyclers, improving ABS waste segregation accuracy by 30% and reducing costs by 15%. This enabled the company to increase recycled ABS content in interiors while meeting safety and performance standards, exemplifying the potential of technology-driven circular economy initiatives.

Read Also: Consumer Metaverse Market

You can place an order or ask any questions. Please feel free to contact us at sales@precedenceresearch.com |+1 804 441 9344

- Aluminum Smelting Market Size to Surpass USD 199.97 Billion by 2034 - September 25, 2025

- Spinosad Active Ingredient Market Size to Reach USD 1,364.27 Million by 2034 - September 25, 2025

- Liquid-Applied Sound-Damping Coating Market Size to Cross USD 376.12 Million by 2034 - September 25, 2025