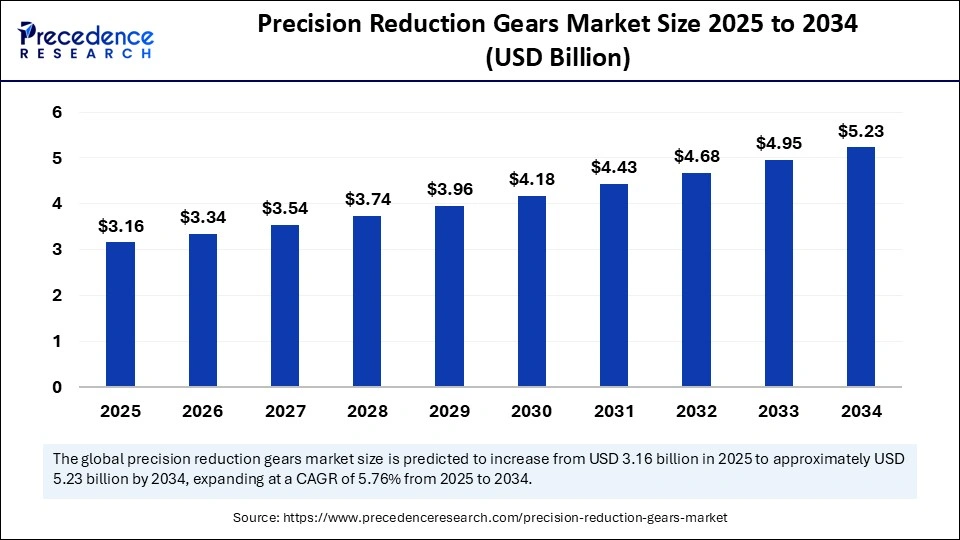

The global precision reduction gears market is poised for significant expansion from USD 3.16 billion in 2025 to an estimated USD 5.23 billion by 2034, representing a compound annual growth rate (CAGR) of 5.76%.

This surge is propelled by increased adoption of automation technologies, robotics, and Industry 4.0 initiatives, which are fueling demand for high-precision gear mechanisms essential to motion control in sectors like aerospace, electric vehicles, semiconductor manufacturing, and medical devices.

What Are Precision Reduction Gears and Why Do They Matter?

Precision reduction gears include advanced gear types such as strain wave gears, planetary gears, and cycloidal gears, which provide accurate speed reduction, torque amplification, and smooth motion essential for applications requiring positioning accuracy, compact size, and durability. These gears are critical components across diversified industries that demand precision and operational reliability.

Precision Reduction Gears Market Key Points

-

The market size for precision reduction gears was USD 2.99 billion in 2024 and is forecasted to grow to USD 5.23 billion by 2034.

-

Asia Pacific emerged as the dominant region, accounting for 41% of the global market share in 2024.

-

North America is the fastest-growing region, supported by innovation in robotics and AI integration.

-

Key industry drivers include automation, growth in electric vehicles, semiconductor manufacturing, and aerospace defense sectors.

-

Strain wave gears hold a dominant market position due to their compact size and superior torque-to-weight ratio.

-

Leading companies in the market focus on lightweight materials, integration of smart sensors, and AI-driven design enhancements.

Precision Reduction Gears Market Revenue Overview (2024–2034)

| Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2024 | 2.99 | – |

| 2025 | 3.16 | 5.76 (2025-2034) |

| 2034 (Est.) | 5.23 | – |

Artificial Intelligence (AI) is revolutionizing the precision reduction gears market by optimizing gear design, testing, and predictive maintenance. Advanced AI algorithms enhance gear geometry modeling and simulate stress loads to maximize efficiency and lifespan. This leads to reduced downtime and maintenance costs, especially in critical sectors like aerospace and robotics.

Moreover, machine learning facilitates the customization of gear products tailored to specific applications, pushing the boundaries of precision engineering. AI-driven automation minimizes production errors, improves scalability, and transforms precision gears into digitally intelligent components rather than mere mechanical parts.

What Are the Key Drivers Behind Market Growth?

The precision reduction gears market growth is primarily fueled by the rapid adoption of automation and robotics in manufacturing, logistics, and healthcare. The surge in electric vehicle production demands highly efficient motion control systems, enhancing the need for advanced reduction gears. Aerospace and defense sectors continue to invest heavily in high-reliability precision gears for mission-critical operations.

Additionally, miniaturization trends in medical devices and semiconductor equipment expand the applications for precision reduction gears, making them indispensable across multiple high-growth industries.

What Opportunities and Trends Are Shaping the Market?

How is the market benefiting from Industry 4.0 and smart manufacturing?

Integration of digital technologies and IoT with precision reduction systems enables smarter, more efficient factories. Predictive maintenance and real-time monitoring improve operational uptime and reduce costs.

What is driving demand for different gear types, particularly strain wave and cycloid gears?

Strain wave gears dominate due to their compact design and torque-to-weight advantages, especially in robotics. Cycloid gears, with their robustness and shock resistance, are rapidly gaining popularity, particularly for heavy-duty applications and emerging semi-automated factories.

How do sustainability and material innovations impact the market?

Eco-friendly lubricants, recyclable materials, and lightweight composites align the market with global sustainability goals, opening new avenues for green precision gear systems.

Precision Reduction Gears Market Regional and Segmentation Highlights

-

Asia Pacific: Leading with 41% market share due to manufacturing capacity and strong automation adoption in China, Japan, and South Korea. The region’s EV and semiconductor industries also boost demand.

-

North America & Europe: Fastest-growing regions, driven by robotics healthcare applications, aerospace, defense technologies, and sustainable manufacturing practices.

-

By Gear Type: Strain wave gears lead market share; cycloidal gears show fastest growth.

-

By Precision Level: High-precision gears are dominant for critical applications; standard precision gears grow in SMEs and emerging markets.

-

By Configuration: Inline reduction gears are most popular due to integration ease; right-angle gears are emerging fast in compact device applications.

-

By Application: Robotics is the largest end-user segment, followed by medical devices and industrial automation.

Precision Reduction Gears Market Companies

- Harmonic Drive Systems Inc.

- Nabtesco Corporation

- Sumitomo Heavy Industries

- WITTENSTEIN SE

- Cone Drive

- Neugart GmbH

- Spinea s.r.o.

- Onvio LLC

- Beijing CTKM Harmonic Drive Co., Ltd.

- Leaderdrive (China)

- GAM Enterprises, Inc.

- KOFON Motion Group

- DieQua Corporation

- Zhejiang Laifual Drive Co., Ltd.

- APEX Dynamics, Inc.

Challenges and Cost Pressures

High initial costs and technical complexities remain barriers to wider adoption, particularly among SMEs. Dependence on specialized raw materials causes vulnerability to supply chain issues. Engineering challenges, including heat buildup and lubrication optimization, limit operational lifespans. Lack of global standardization also restricts interoperability.

Case Study Snapshot

A leading semiconductor equipment manufacturer recently integrated AI-optimized strain wave gears into robotic wafer handling systems, achieving a 15% boost in production efficiency and a 20% reduction in maintenance downtime, underscoring the transformative impact of AI in precision reduction.

Read Also: Hydraulic Hose Market

You can place an order or ask any questions. Please feel free to contact us at sales@precedenceresearch.com |+1 804 441 9344

- Aluminum Smelting Market Size to Surpass USD 199.97 Billion by 2034 - September 25, 2025

- Spinosad Active Ingredient Market Size to Reach USD 1,364.27 Million by 2034 - September 25, 2025

- Liquid-Applied Sound-Damping Coating Market Size to Cross USD 376.12 Million by 2034 - September 25, 2025