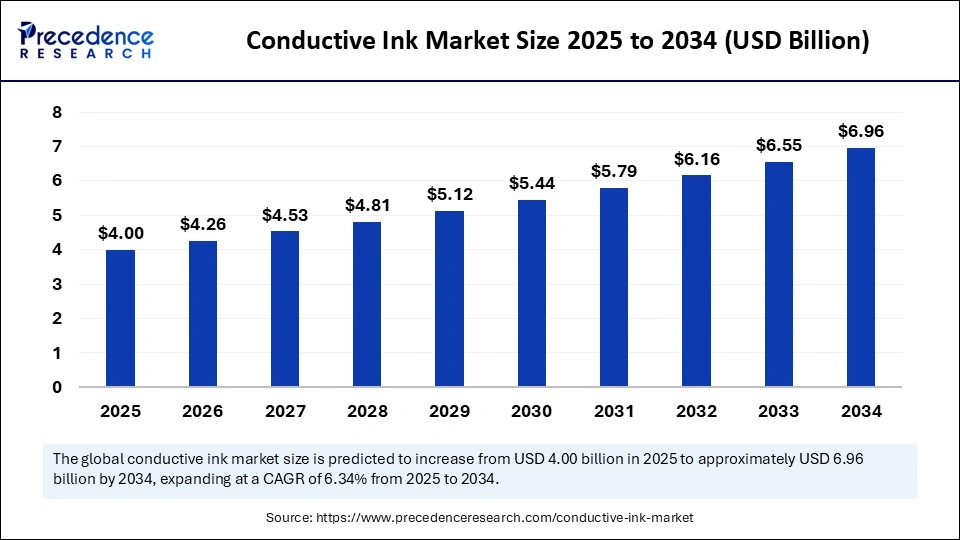

The global conductive ink market, valued at USD 3.76 billion in 2024, is set to grow to approximately USD 6.96 billion by 2034, with a forecasted CAGR of 6.34% between 2025 and 2034. This surge is powered by booming demand for advanced printed electronics, flexible displays, automotive electrification, and the increasing role of renewable energy solutions especially solar photovoltaics across key regions.

Conductive Ink Market Key Insights

-

The market is forecasted to reach USD 6.96 billion by 2034, growing from USD 4.00 billion in 2025.

-

Asia Pacific claims the largest regional share, led by China, Japan, and South Korea’s manufacturing dominance.

-

North America is the fastest-growing market, propelled by EV adoption and investments in flexible electronics.

-

Silver-based inks remain dominant, while copper-based inks are poised for fastest segment growth due to cost and sustainability factors.

-

The photovoltaics segment leads by application, with flexible displays and touchscreens set for rapid expansion.

-

Screen printing is the reigning technology, while inkjet printing rises for high-precision electronics.

-

Glass is the top substrate, with flexible plastics gaining market momentum.

-

Consumer electronics and automotive are key end-use industries, reflecting shifts toward EVs and wearables.

Conductive Ink Market Revenue Table: Market Breakdown

| Year | Market Size (USD Billion) |

|---|---|

| 2024 | 3.76 |

| 2025 | 4.00 |

| 2034 | 6.96 |

AI is rapidly revolutionizing the conductive ink sector by ushering in smarter manufacturing and materials development. Materials informatics platforms—AI-powered modeling systems—now help companies optimize conductive ink formulations, refining resistivity and curing characteristics far more efficiently than manual laboratory testing.

In manufacturing, machine learning-enhanced techniques monitor and adjust conductive ink deposition in real time, leading to higher print quality and superior electrical performance. These AI-driven methods speed up innovation and make customization easier, helping manufacturers deliver tailored solutions for next-generation electronics, wearables, and auto applications.

Get this report to explore global market size, share, CAGR, and trends, featuring detailed segmental analysis and an insightful competitive landscape overview @ https://www.precedenceresearch.com/sample/6753

What Factors Are Driving Market Growth?

The market’s growth is anchored by several compelling drivers:

-

The expansion of renewable energy—especially solar photovoltaics—boosts demand for conductive inks, which are critical for printing energy-transmitting lines in solar cells.

-

Flexible and wearable electronics are on the rise, with conductive inks enabling the direct printing of circuits on plastics, textiles, and other substrates. This supports product innovation in foldable phones, wearables, and remote health monitoring technologies.

-

The adoption of copper-based inks — more affordable and eco-friendly—unlocks applications in mass-market printed electronics, while anti-oxidation advances reduce downsides.

Conductive Ink Market Opportunity and Trends

How Will EVs and Smart Automotive Electronics Transform the Market?

The electrification of vehicles and integration of smart systems create abundant opportunities for conductive ink producers. Lightweight, flexible, and printed electronics reduce traditional wiring complexity in battery management, ADAS, and interactive surfaces, supporting next-gen automotive design.

Can Healthcare’s Shift to Wearables Fuel New Growth?

Rapid innovation in wearable medical devices and biosensors demands conductive inks that deliver biocompatibility, flexibility, and dependable electrical performance. Healthcare’s focus on remote monitoring and chronic disease management further accelerates this trend, with conductive inks powering affordable health technology platforms.

Are Sustainability and Cost Driving Material Choices?

Absolutely. Manufacturers and end-users seek cost-effective, sustainable alternatives such as copper-based and carbon-based inks, with research focused on anti-oxidation and durability. This flexibility enables broader adoption in solar, consumer electronics, and automotive sectors.

Conductive Ink Market Regional and Segmentation Analysis

-

Asia Pacific dominates, valued at USD 1.80 billion in 2025 and projected to reach USD 3.17 billion by 2034, thanks to robust manufacturing infrastructure, government support, and demand for consumer electronics and solar panels.

-

North America is set for the fastest growth due to its innovative ecosystem and high EV and renewable energy investments.

-

Segmentation by Type, Application, Technology, Substrate, End-Use Industry, and Region reveals that silver-based inks and screen printing technology are preferred for high-reliability applications; copper-based inks, inkjet processes, and flexible plastic substrates are rapidly expanding for mass-market and advanced applications.

-

Top Applications include photovoltaics (solar panels), RFID tags, flexible displays, sensors, medical patches, and ADAS for automobiles.

Conductive Ink Market Companies

- Henkel AG & Co. KGaA

- DuPont de Nemours, Inc.

- Sun Chemical Corporation

- Heraeus Holding GmbH

- Johnson Matthey Plc

- NovaCentrix

- Poly-ink

- Applied Ink Solutions

- Vorbeck Materials Corporation

- Creative Materials Inc.

- Intrinsiq Materials

- PPG Industries Inc.

- Nagase & Co., Ltd.

- Toyo Ink SC Holdings Co., Ltd.

- Methode Electronics, Inc.

Challenges and Cost Pressures

The sector faces high input costs, particularly for silver-based inks, which dominate key applications despite ongoing advances in copper and carbon ink alternatives. Technical trade-offs—balancing conductivity, flexibility, adhesion, and durability—require complex formulations and sometimes restrict scalability for certain substrates and environments, challenging widespread adoption and profitability.

Case Study: Solar Panel Manufacturing Transformation

A major solar panel maker in Asia Pacific recently cut production costs and improved energy conversion efficiency by switching from all-silver inks to advanced copper formulations optimized via AI-based materials informatics. This move slashed raw material costs, boosted durability against oxidation, and increased output, underscoring the transformative impact of innovation in conductive ink materials and manufacturing.

Read Also: U.S. Environmental Remediation Market

You can place an order or ask any questions. Please feel free to contact us at sales@precedenceresearch.com |+1 804 441 9344

- Multi-Access Edge Computing Market Size to Reach USD 259.50 Billion by 2034 - September 12, 2025

- Storage Area Network Market Size to Surpass USD 36.63 Billion by 2034 - September 12, 2025

- Ambient Computing Market Size to Reach USD 448.89 Billion by 2034 - September 12, 2025