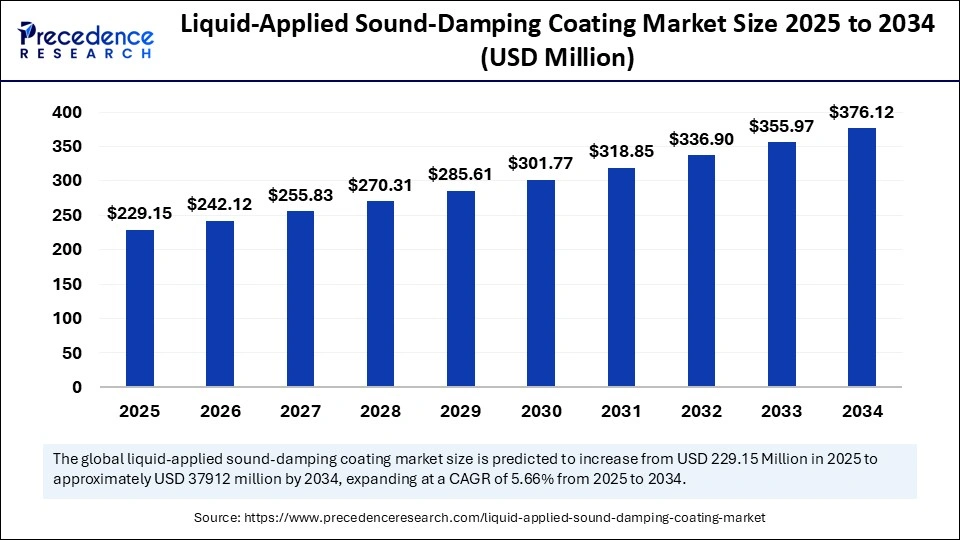

The global liquid-applied sound-damping coating (LASD) market size was valued at USD 216.88 million in 2024 and is projected to grow to approximately USD 376.12 million by 2034, representing a compound annual growth rate (CAGR) of 5.66% from 2025 to 2034.

This expansion is primarily propelled by the increasing demand for efficient noise reduction across the automotive, aerospace, construction, and industrial sectors, driven by a growing focus on lightweight, sustainable, and high-performance noise and vibration control solutions.

Liquid-Applied Sound-Damping Coating Market Highlights

-

The market size was USD 216.88 million in 2024, projected to grow to USD 376.12 million by 2034.

-

North America is the dominant market region, while Asia Pacific is the fastest-growing region.

-

Top industry drivers include electric vehicles (EVs) and aerospace cabin comfort requirements.

-

Water-based LASD coatings lead in revenue due to environmental sustainability and regulatory compliance.

-

Spray-applied coatings are the most commonly used application method.

-

Major players shaping the market include automotive OEMs and aerospace manufacturers investing in R&D and automation.

Get this report to explore global market size, share, CAGR, and trends, featuring detailed segmental analysis and an insightful competitive landscape overview @ https://www.precedenceresearch.com/sample/6844

How Is Artificial Intelligence Transforming the LASD Market?

Artificial intelligence (AI) is revolutionizing the LASD coating industry by optimizing product development and manufacturing processes. AI-driven modeling and simulation enhance the creation of advanced formulations with superior acoustic properties, fire resistance, and durability.

In manufacturing, AI improves precision in spray dispersion and coating thickness control, reducing material waste and increasing production efficiency. Additionally, AI-powered predictive maintenance minimizes equipment downtime, ensuring cost-effective operations. AI tools also help forecast market trends by analyzing consumer demand and regulatory changes, enabling companies to maintain competitiveness in a dynamic environment.

What Are the Key Growth Factors for the LASD Coating Market?

The LASD coating market is growing due to the rising need for lightweight, effective noise and vibration control solutions in the automotive and aerospace sectors. Electric vehicle adoption highlights the importance of low-noise technology, as EVs amplify secondary sounds like road and wind noise.

Stricter noise regulations worldwide compel manufacturers to adopt advanced damping solutions that balance performance with cost-efficiency. The preference for automated manufacturing processes further drives LASD coatings’ adoption by reducing labor costs while enhancing throughput and consistency.

Market Scope

| Report Coverage | Details |

| Market Size in 2024 | USD 216.88 Million |

| Market Size in 2025 | USD 229.15 Million |

| Market Size by 2034 | USD 376.12 Million |

| Market Growth Rate from 2025 to 2034 | CAGR of 5.66% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Material Composition, Application Method, Thickness Range, End-Use Industry, Distribution Channel, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

What Opportunities and Trends Are Emerging in the Market?

Why is demand for water-based LASD coatings increasing?

Water-based coatings are gaining traction due to their significantly lower volatile organic compound (VOC) emissions, aligning well with global sustainability goals and regulatory mandates. These coatings are widely accepted in the automotive industry, where environmental compliance is critical without sacrificing performance.

How are hybrid polymer LASD coatings impacting the market?

Hybrid coatings, combining advanced polymers and fillers, deliver enhanced noise damping across a broader frequency range along with superior fire resistance and durability. They are increasingly adopted in EVs, aerospace, and industrial machinery, where high resistance to vibration and environmental stress is essential.

What role does the automotive segment play in market growth?

Passenger vehicles dominated revenue share in 2024, primarily due to the widespread need for NVH (noise, vibration, and harshness) control to improve cabin comfort. The EV sub-segment is growing rapidly, driven by the need for lightweight, efficient acoustic materials that support extended battery life and quieter operation.

How Is the Market Segmented Regionally and by Application?

The Asia Pacific region leads the market, commanded by rapid growth in automotive manufacturing and infrastructure development in countries like China, India, Japan, and South Korea. Government policies promoting green manufacturing and stringent workplace noise regulations have accelerated adoption.

North America is forecasted to register the fastest CAGR, with strict noise laws and a strong focus on automotive and aerospace innovations fueling demand.

Segmentation highlights:

By type: Water-based coatings dominate due to environmental benefits.

By material: Acrylic coatings lead revenue, prized for cost-effectiveness and versatility.

By application method: Spray application is prevalent for its efficiency and adaptability.

By thickness range: 1–2 mm coatings provide optimal noise dampening with cost balance.

By end-use industry: Automotive passenger vehicles hold the largest market share; EVs show the fastest growth.

By distribution channel: Direct sales through OEM contracts account for the majority revenue share.

Liquid-Applied Sound-Damping Coating Market Companies

- Henkel AG and Co. KGaA

- 3M Company

- PPG Industries, Inc.

- BASF SE

- Dow Chemical Company

- Sika AG

- Covestro AG

- LORD Corporation

- Daubert Chemical Company

- RPM International Inc.

- Mascoat

- Ziebart International Corporation

- L&L Products

- Soundcoat Company, Inc.

- Tremco Incorporated

- Akzo Nobel N.V.

- Kansai Paint Co., Ltd.

- Axalta Coating Systems

- Sherwin-Williams Company

- Nippon Paint Holdings Co., Ltd.

What Challenges Affect the LASD Market?

Despite positive growth, the market faces challenges including relatively high application costs, especially burdensome for small and mid-sized manufacturers. Technical limitations exist as LASD coatings are more effective with medium-frequency noise, while conventional mats still better handle low-frequency damping. Balancing performance, cost, and sustainability continues to be a critical hurdle for broader adoption.

Case Study: EV Manufacturer Boosts Acoustic Comfort with LASD

An electric vehicle manufacturer integrated water-based LASD coatings into critical cabin and underbody components, achieving a notable reduction in NVH without adding significant weight. By adopting AI-assisted robotic spraying, the production efficiency improved, reducing material waste and cycle times, resulting in enhanced cabin comfort and extended battery range.

Read Also: EFEM and Sorters Market

You can place an order or ask any questions. Please feel free to contact us at sales@precedenceresearch.com |+1 804 441 9344

- Aluminum Smelting Market Size to Surpass USD 199.97 Billion by 2034 - September 25, 2025

- Spinosad Active Ingredient Market Size to Reach USD 1,364.27 Million by 2034 - September 25, 2025

- Liquid-Applied Sound-Damping Coating Market Size to Cross USD 376.12 Million by 2034 - September 25, 2025