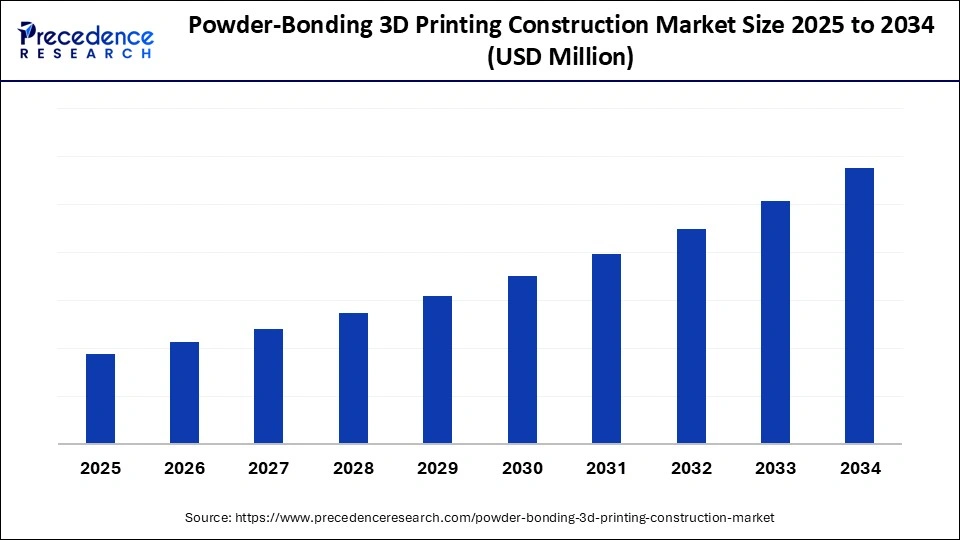

The powder-bonding 3D printing construction market is set to witness impressive growth, fueled by an expected compound annual growth rate (CAGR) exceeding 12% between 2025 and 2034. This rapid expansion is driven by escalating global infrastructure needs, housing shortages, and technological breakthroughs such as AI integration and innovative powder materials like geopolymers.

Governments worldwide are backing 3D printing methods due to their unparalleled advantages in reducing construction time, cost, and carbon footprint while enabling design freedom and precision.

Powder-Bonding 3D Printing Construction Market Key Insights

-

The global market for powder-bonding 3D printing construction is dominantly led by North America, which holds around 36% of the market share as of 2024.

-

The Asia Pacific region is forecasted to grow the fastest, propelled by rapid urbanization and government investments in smart, sustainable cities.

-

The binder jetting technology commands the largest share of nearly 58%, favored for its speed, material versatility, and cost-effectiveness.

-

Among construction materials, concrete leads with about 54% share due to its availability, affordability, and strength.

-

Residential construction accounts for roughly 49% of the market, reflecting the urgent demand for affordable, fast-built housing solutions.

-

Key players shaping the market include Voxel Jet, COBOD International, Simpliforge Creations, XtreeE, Epuls3D, Wipro 3D, Vexma Technologies, and Incredible AM.

Get this report to explore global market size, share, CAGR, and trends, featuring detailed segmental analysis and an insightful competitive landscape overview @ https://www.precedenceresearch.com/sample/6725

Market Revenue Breakdown and Segmentation

The market is segmented by technology, material type, construction type, end user, and region. Binder jetting held nearly 58% market share in 2024, followed by the powder bed fusion segment, which is expected to grow fastest with a CAGR of approximately 12.8% during the forecast period. Concrete dominates material usage with 54%, while composite powders are the fastest-growing segment, evolving with features like embedded sensors for monitoring structural health.

Construction application segmentation reveals building construction with a 61% share, favored by developers for cost and labor efficiency, whereas infrastructure construction is projected to grow fastest at about 14.1% CAGR due to smart city development and integration of IoT technologies.

Residential end users hold the largest market share near 49%, meeting demands for sustainable and rapid housing, whereas industrial construction is set for fastest growth with a CAGR near 13.8%, driven by precision and automation needs.

The Role of AI in Powder-Bonding 3D Printing Construction

Artificial intelligence has revolutionized the powder-bonding 3D printing construction sector by improving design, planning, and quality control through AI-driven process optimization and defect detection. AI models like convolutional neural networks (CNN) analyze each printed layer to identify and fix defects in real-time, vastly enhancing print precision and reliability.

Moreover, AI-based automation reduces human error, accelerates project completion times, and optimizes resource use, contributing to more cost-effective and sustainable construction. By predicting material behaviors under various conditions through real-time data analytics, AI ensures higher success rates of powder bonding 3D printing applications on a large scale.

What Are the Key Growth Factors Driving This Market?

The primary drivers of market growth include the tremendous cost and time savings powder-bonding 3D printing offers over traditional construction. This technology drastically reduces labor costs and material waste while providing energy-efficient and carbon-neutral construction options like geopolymer powders. Innovation and freedom in design capability enable the production of intricate, lightweight, and durable structures, attracting investments from governments focused on building smart, eco-friendly cities.

Technological advances in binder jetting and powder bed fusion techniques further propel adoption by enabling faster, more versatile, and higher precision construction processes suitable for various materials, including metals and composites in industrial applications.

What New Opportunities and Trends Are Emerging in Powder-Bonding 3D Printing?

How is innovation shaping the future of the powder-bonding 3D printing construction market?

Innovation leads to unprecedented design freedom, allowing intricate and lightweight parts that are difficult or impossible with conventional methods. Innovative materials, such as composite powders embedding sensors, open new avenues for structural health monitoring and longevity improvements.

What role does government support play in accelerating market growth?

Governments worldwide support the market by providing financial incentives, tax exemptions, and funding for research aimed at sustainable urbanization. This is particularly evident in North America and Asia Pacific where smart city projects align with eco-friendly construction initiatives.

Regional and Segmentation Analysis

North America dominates due to strong government backing, eco-conscious construction demands, and significant R&D investment that leads to innovative practices such as co-investment mechanisms and demonstration builds. Asia Pacific is projected to accelerate the fastest, fueled by urban population growth and national policies investing heavily in automation and smart city construction aligned with environmental regulations.

By technology, binder jetting remains dominant for its versatility and low cost, while powder bed fusion is rapidly gaining traction for industrial and high-precision needs. Concrete remains the favored material given its availability and adaptability, though composite powders are emerging as futuristic alternatives with embedded functionalities.

In construction type, building projects lead due to cost-efficiency and design flexibility, with infrastructure applications rising fast to meet the growing digital and connected city infrastructure needs. Residential and industrial sectors reflect the largest and fastest growing end user demands respectively based on urbanization and precision construction needs.

Latest Breakthroughs and Company Innovations

Leading companies such as Voxel Jet and COBOD International have pioneered rapid binder jetting technologies suitable for large-scale production. Other market players like Epuls3D and Wipro 3D focus on developing next-gen powder bonding materials and service bureaus specialized in advanced additive manufacturing.

- COBOD International

- ICON Technology, Inc.

- Apis Cor

- Winsun Construction Engineering

- XtreeE

- CyBe Construction

- PERI Group

- Sika AG

- WASP Srl

- Constructions-3D

- LafargeHolcim

- BetAbram

- Mighty Buildings

- Branch Technology

- SQ4D

Challenges and Cost Pressures

Despite its promise, the powder-bonding 3D printing construction market faces several hurdles, including high initial capital expenditure for 3D printing machinery and setups. Post-processing complexities and limited material certifications add to operational costs, which can be prohibitive, especially for smaller firms. The need for sophisticated infrastructure and training also limits immediate widespread adoption.

Case Study: Accelerating Affordable Housing with 3D Printing

In a recent pilot project in North America, a 3D printed residential community was constructed using binder jetting technology combined with geopolymer concrete. This project reduced construction time by 40% and cut labor costs by over 50%, while meeting stringent environmental standards. The success of this pilot validated 3D printing as a viable solution for emergency and affordable housing, encouraging further governmental support and private sector investment.

Read Also: Co-Packaged Optics Market

You can place an order or ask any questions. Please feel free to contact us at sales@precedenceresearch.com |+1 804 441 9344

- Powder Bonding 3D Printing Construction Market Build complex formwork with precision, customization, and sustainable design - September 9, 2025

- Protein Characterization and Identification Market Set to Reach USD 8.04 Billion by 2034 Fueled by 5.29% CAGR and AI-Driven Innovations - September 9, 2025

- Automotive Simulation Software Market Size to Cross USD 24.35 Billion by 2034 - September 8, 2025