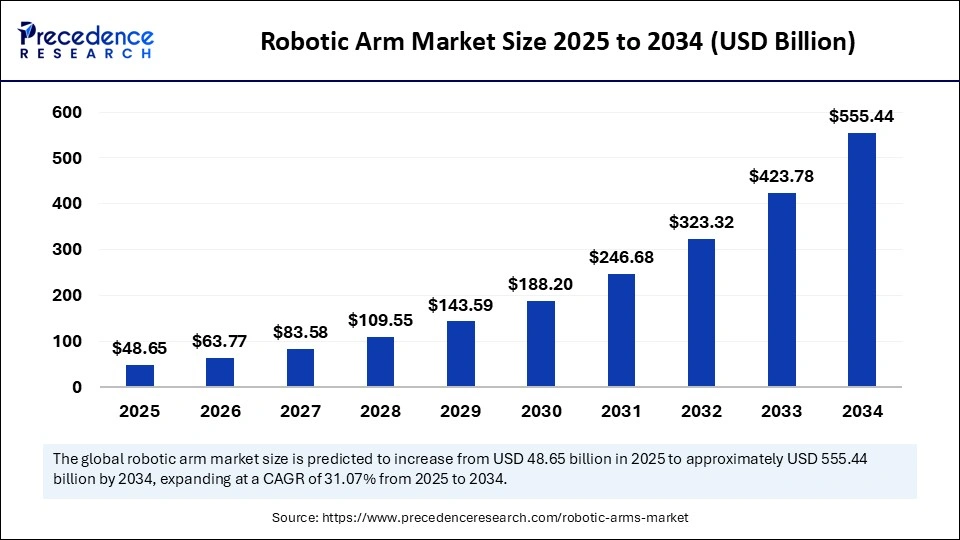

The global robotic arm market is on an unprecedented growth trajectory, expected to leap from USD 63.77 billion in 2025 to a staggering USD 555.44 billion by 2034, registering a robust CAGR of 31.07%.

This surge is propelled by accelerating industrial automation, the proliferation of Industry 4.0, and cutting-edge technological advancements, including Artificial Intelligence (AI) and collaborative robots (cobots).

What Are the Key Drivers Accelerating the Robotic Arm Market Growth?

The market thrives on expanding demand across manufacturing, logistics, and assembly sectors seeking productivity enhancements and operational cost reductions. Labor shortages and increasing complexity in manufacturing processes further fuel adoption. The adaptability of robotic arms, mimicking human arm functions with precision and speed, anchors their popularity in industrial production and assembly lines worldwide.

Robotic Arm Market Key Insights

-

The market size reached USD 48.65 billion in 2024 and is anticipated to hit USD 63.77 billion in 2025.

-

Asia Pacific dominates with 50% of the global market share, led by rapid industrialization and government automation initiatives.

-

The articulated robotic arm segment holds a 40% market share in 2024, driven by SME demand and Industry 4.0.

-

The automotive sector commands 35% of the market share, with applications in welding, painting, assembly, and inspection.

-

Key industry leaders include ABB Robotics, Stäubli Robotics, Flexiv, Accenture, and Schaeffler AG.

-

The CAGR from 2025 to 2034 is forecasted at 31.07%, projecting the market value to grow beyond USD 555 billion by 2034.

Market Scope

| Year | Market Size (USD Billion) |

|---|---|

| 2024 | 48.65 |

| 2025 | 63.77 |

| 2034 | 555.44 |

AI integration is revolutionizing robotic arm capabilities by enabling machines to learn from experience and adapt autonomously to complex and dynamic environments. This intelligence facilitates enhanced precision, operational efficiency, and collaboration between humans and robots across diverse sectors such as healthcare, automotive, and logistics. AI-driven robotic arms employ machine learning algorithms for optimized task management, predictive maintenance, and real-time environmental sensing, substantially boosting productivity and reducing operational costs.

Furthermore, AI-powered robotic arms simulate human-like decision-making, enabling them to handle unpredictable tasks and work safely alongside humans. These innovations pave the way for versatile automation solutions addressing labor shortages and complex production demands globally.

What Factors Are Driving Market Growth?

The surge in demand for automation across industries, particularly for cost reduction and productivity, underpins growth. Strategic initiatives embracing Industry 4.0, advancements in robot flexibility and dexterity, and increasing SME automation adoption further accelerate market expansion. The burgeoning need for precise, repetitive task automation in sectors including automotive, electronics, pharmaceuticals, and logistics is a significant growth driver.

What Market Opportunities and Trends Are Emerging?

Which segments show promising growth potential?

The collaborative robot (cobot) segment is rapidly expanding, offering safer, more adaptable alternatives by integrating AI and IoT technologies. Material handling applications dominate with a 30% share, with rapid growth expected in dispensing and precision tasks.

How is regional growth shaping market dynamics?

Asia-Pacific leads the market, buoyed by rapid industrialization, government initiatives, and increasing investments by global robotics manufacturers. North America and Europe continue to advance with innovations in AI-enabled robotics and adoption in healthcare and manufacturing.

What latest technological breakthroughs are notable?

ABB Robotics introduced OmniCoreEyeMotion for advanced real-time perception enabling superior robot adaptability. Stäubli Robotics developed mobile robots for pharmaceutical cleanrooms enhancing automation in sensitive environments. Flexiv launched a force-control simulation app to integrate AI in robotic programming and testing environments. Accenture and Schaeffler AG showcased next-generation human-robot collaboration and full automation scenarios using AI and advanced simulation.

Robotic Arm Market Segmentation Analysis

-

By Type: Articulated arms dominate with a 40% share due to versatility; collaborative arms expected to grow fastest due to AI and IoT integration.

-

By Application: Material handling leads with 30%, propelled by logistics and e-commerce; dispensing poised for significant growth in pharma and electronics.

-

By End-Use Industry: Automotive leads with 35% market share, followed by manufacturing and healthcare sectors adopting robotic precision for assembly and inspection.

-

By Region: Asia Pacific commands half the market, driven by China, Japan, and India; North America and Europe focus on innovation-driven growth.

Robotic Arm Market Companies

- Doosan Robotics

- DENSO Corporation

- FANUC

- KUKA

- Yaskawa Electric Corporation

- Universal Robots

- Epson Robots

- Kawasaki Heavy Industries

- Comau

- Nachi-Fujikoshi Corporation

- Mitsubishi Electric Corporation

- Omron Corporation

- Techman Robot

- AUBO Robotics

- EFORT Intelligent Equipment

- Estun Automation

- Siasun Robot & Automation

Challenges and Cost Pressures

Despite rapid growth, challenges such as high initial investment costs, integration complexities, and concerns over workforce displacement remain. Maintaining a balance between automation benefits and human labor dynamics is crucial. Additionally, cost pressures linked to advanced sensor technologies and AI implementation require strategic management.

Case Study Highlight

A prominent pharmaceutical company partnered with Stäubli Robotics to develop mobile cleanroom robots, automating production and ensuring compliance with stringent environmental standards. This collaboration exemplifies innovation in automating sensitive manufacturing processes with robotic arms, enhancing safety and efficiency.

Segments Covered in the Report

By Type

- Articulated

- Cartesian

- SCARA

- Delta

- Polar

- Collaborative

By Application

- Material Handling

- Welding

- Assembly

- Dispensing

- Processing

- Inspection

By End-Use Industry

- Automotive

- Electronics

- Metals & Machinery

- Food & Beverages

- Pharmaceuticals

- Aerospace & Defense

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Read Also: 3D Protein Structures Analysis Market

You can place an order or ask any questions. Please feel free to contact us at sales@precedenceresearch.com |+1 804 441 9344

- Robotic Arm Market Size to Touch USD 555.44 Billion by 2034 - October 13, 2025

- In Vivo Cell Reprogramming Market to Reach Significant Valuation by 2034 with Rapid Growth Driven by Regenerative Medicine Innovations - October 13, 2025

- Air Freight Forwarding System Market Size to Soar to USD 13.61 Billion by 2034 with 4.33% CAGR Growth Forecast - October 13, 2025